Welcome to Green Innovation

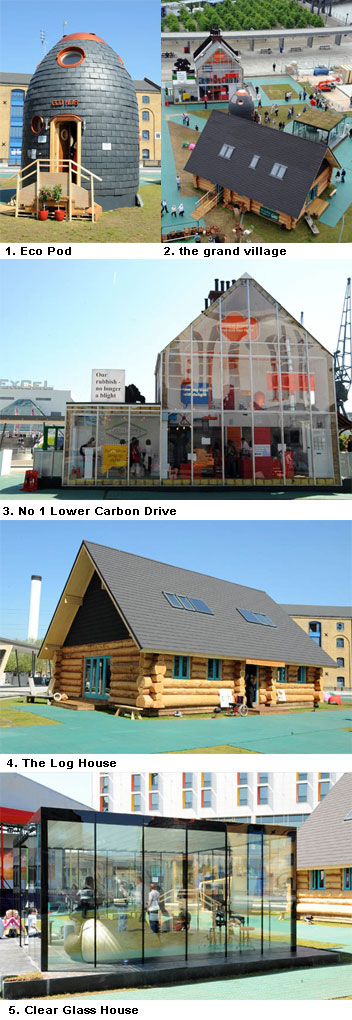

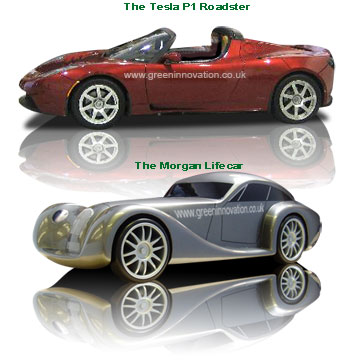

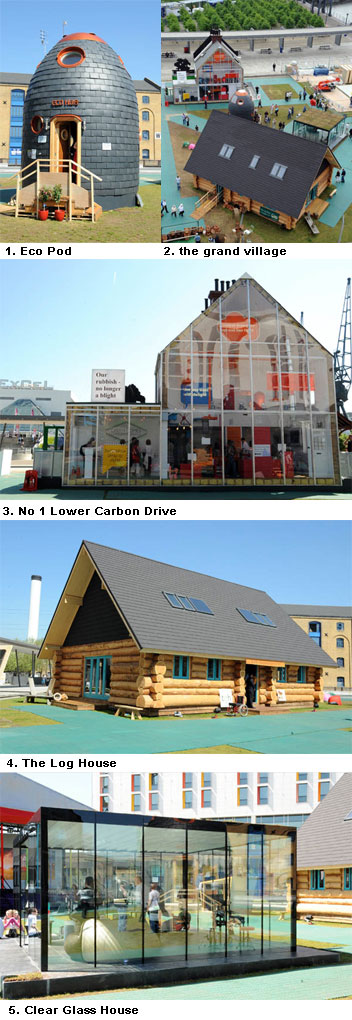

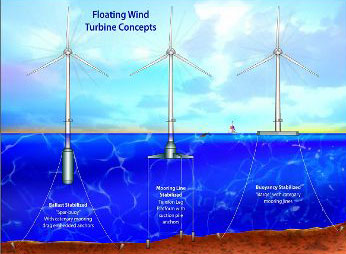

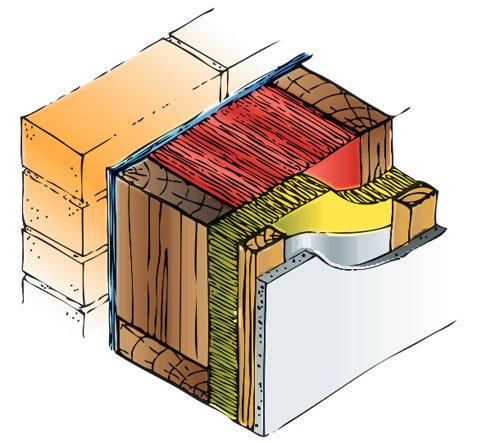

green technology & eco friendly homes

Eco Friendly 3d Printers

3D Printers are machines that can make any 3D objects, much like we use inkjet printers today for two-dimensional paper objects. Read Printers 3D for more.

This technology will change manufacturing worldwide. Currently the manufacture of products is costly time and in terms of the carbon released by the process: a design team creates an object, which is then manufactured in a far-away factory and physically shipped from the factory to a distribution center, where they await customer orders. Upon order receipt, the item is shipped typically to a retail location, where it sits again until a buyer travels to the store and finally picks it up off the shelf and transports it home, where it can be used.

With the introduction of 3D printers this could change significantly in the future: A design team creates an object, but merely stores the 3D design in an online repository. The client purchases access to the design and loads it into an in-home 3D printer. The printer reproduces the object to the specifications in the 3D design and the object can be used.

No more inventory, no more shipping, no more big boxes and packaging. This change would almost completely negate carbon emissions due to the shipping of all these 3D printed objects.

Not only will objects be possible to produce on such devices, but food as well. Many food items are simply physical arrangements of ingredients, and this will be quite possible to prepare using standard or modified 3D printing devices. Just as highly complex objects can be printed, so can normally impossible food items to produce with traditional approaches.

© Copyright 2004-2026 - greeninnovation

Eco Friendly 3d Printers

disclaimer | sitemap | links